Wiring Plan:

As shown in our post about the watertight compartment, we plan to have five major cables (one in each cord grip) run from electronics to inside the compartment – three entering the from the front and two from the back.

Front

The three cables protruding from the front are organized in the following way:

- One has seven wires and will be for the two small thrusters in the front have.

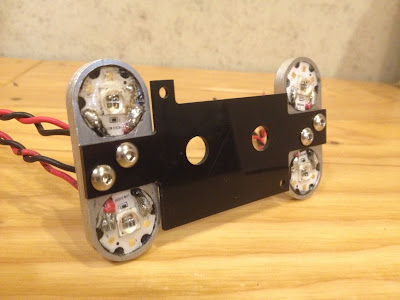

- One has eight wires, two for each of four LEDs.

- And the final cable has eighteen wires that will connect to the camera, servo motor, IMU, depth sensor, and two LIDARs.

Rear

The two cables to the back are split so that:

- One has ten wires which will run to both small thrusters and the large thruster in the back half.

- The second has three wires which run out the top of the sub to act as our tether, as in this post.

Wiring the Loom:

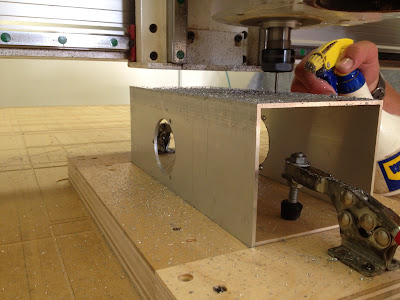

Because we spent more time planning the actual process of wiring the loom didn't take too long. Inspired by the power supply we bought, we came up with a good way of organizing the wires.

We stripped the large cables far enough back that we had all the free wire we needed to route and solder our electronics in place.

We then grouped wires based on the final destination (e.g. three for each small thruster or four to the USB cable) and put them in sleeving.

Then to keep the sleeving from fraying we zip-tied each end and covered it with heat shrink.

This process was the same for all of our components. We also added two more organizational ideas to make the wiring easy to follow.

First, we used coordinated the heat shrink to show the function of each set of wires. For example we made the horizontal thrusters with blue heat shrink and the vertical thrusters with yellow heat shrink (as pictured above).

Second, we got wire markers (numbered/lettered stickers) to label similar looking parts. For example, we labeled each of the motor controllers and used labels to indicate which side of connectors went to ground.

We covered all of our solder joints – on top of all the sleeving – with similarly colored heat shrink, making sure to put liquid electrical tape on each one first to help with water proofing.

The last precaution that we took against any leakage was epoxying the ends of the cable. We did this because it is possible for water to enter the cables and work its way into the watertight compartment inside the casing as it can bypass the cord grips.

The zip tie in the picture ensures that the epoxy does not drip too far into the cable compromising the effectiveness of the plug. We cut a small slit in each of the cables so that we could fill it with epoxy,

then used a zip-tie to keep the epoxy tightly packed in the top 1/4" of the cable.

Below we have two pictures of the sub. One before wiring the loom and one of after wiring the loom.

The last precaution that we took against any leakage was epoxying the ends of the cable. We did this because it is possible for water to enter the cables and work its way into the watertight compartment inside the casing as it can bypass the cord grips.

|

| Cable with Epoxy |

then used a zip-tie to keep the epoxy tightly packed in the top 1/4" of the cable.

Below we have two pictures of the sub. One before wiring the loom and one of after wiring the loom.

|

| Before Wiring the Loom |

|

| After Wiring the Loom |